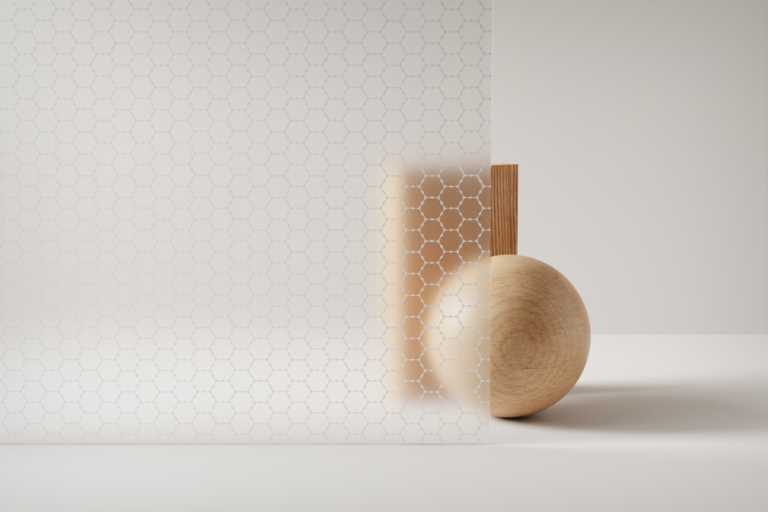

Create a Product With Us

We can partner with you in a number of ways across a full suite of products. Start with a pattern from our offering or provide us with your mood board for custom product development. Not sure where to start? Reach out and we’ll make a plan together.

- Custom colors

- Wallcovering and wall murals

- Textiles for upholstery and panel

- Drapery and privacy curtains

- Glass film

- Rugs

- And more